Rebar Coupler

A rebar coupler is a mechanical device used to connect two pieces of reinforcing steel (rebar) together in a concrete structure. These devices are used in place of traditional lap splicing to create a stronger, more reliable connection between the rebar. There are several different types of rebar couplers available, including mechanical splice couplers, sleeve couplers, and welding couplers. They are used to extend the length of rebar, and to join rebar of different diameters.

Use of rebar coupler

Rebar couplers are used to connect reinforcing steel bars (rebar) in a concrete structure, allowing for the creation of longer and stronger connections between the rebar. This can improve the overall strength and stability of the structure and reduce the amount of rebar required. They are also used to join rebars of different diameters, which can help simplify the construction process and reduce the number of different sizes of rebar needed on a project. Additionally, they can be used to connect rebar at an angle, which can be useful when building structures with curved or angled walls.

Rebar couplers are widely used in building construction, bridges, infrastructure, and precast elements. Due to their ability to provide a secure and reliable connection, they are also used in seismic and post-tensioned applications.

Types of Rebar Coupler

There are several different types of rebar couplers available, including:

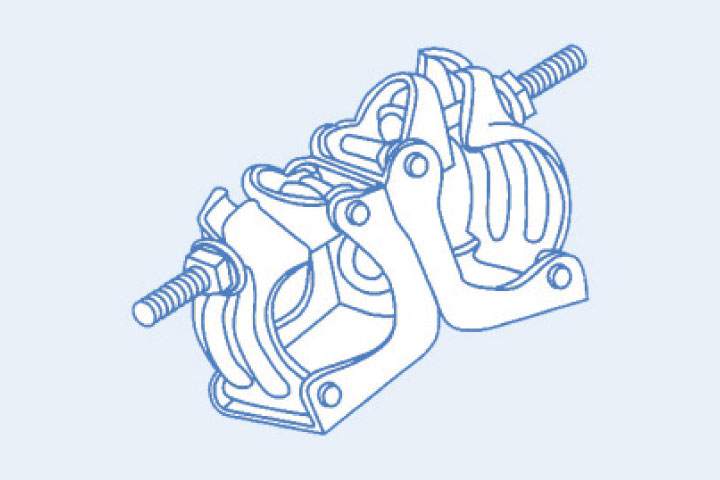

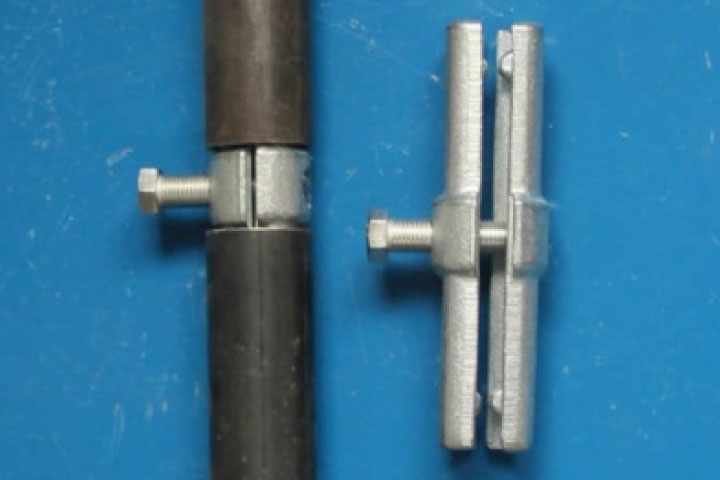

- Mechanical splice couplers: These couplers use a mechanical connection, such as a threaded connection or a wedge-shaped connection, to join two pieces of rebar together. They are easy to install and provide a strong, reliable connection.

- Sleeve couplers: These couplers consist of a metal sleeve that fits over the ends of two pieces of rebar, holding them together. They are typically used for rebar of the same diameter, and they can be used to connect rebar at an angle.

- Welding couplers: These couplers use welding to join two pieces of rebar together. They provide a very strong connection, but they require specialized equipment and trained personnel to install.

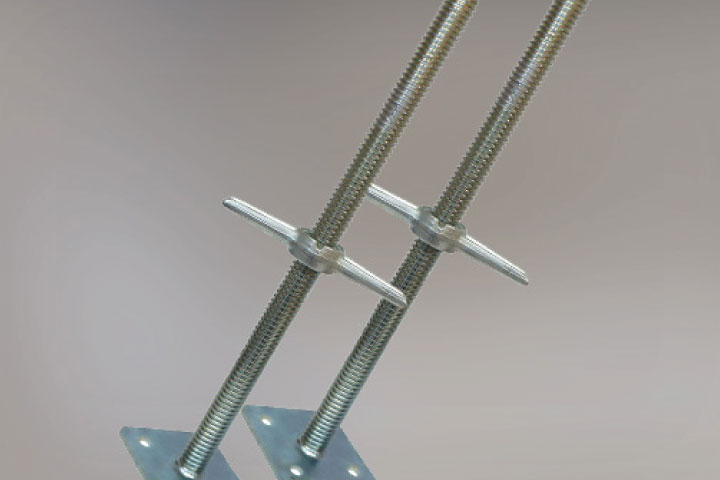

- Parallel Threaded Rebar Coupler: These types of couplers are used to connect two bars of the same or different diameters and have a parallel thread on the inside. They are screwed into the rebar end and provide a secure connection.

- Tapered Threaded Rebar Coupler: These types of couplers are used to connect two bars of the same or different diameters and have a tapered thread on the inside. They are screwed into the rebar end and provide a secure connection.

- Cold-Forged Rebar Coupler: These types of couplers are made by forging and deforming the rebar end in cold condition. They are commonly used for connecting high strength rebar and have a high-performance connection.

The choice of which type of coupler to use will depend on the specific requirements of the project, including the size and strength of the rebar being used, the location and orientation of the connection, and the equipment and personnel available.