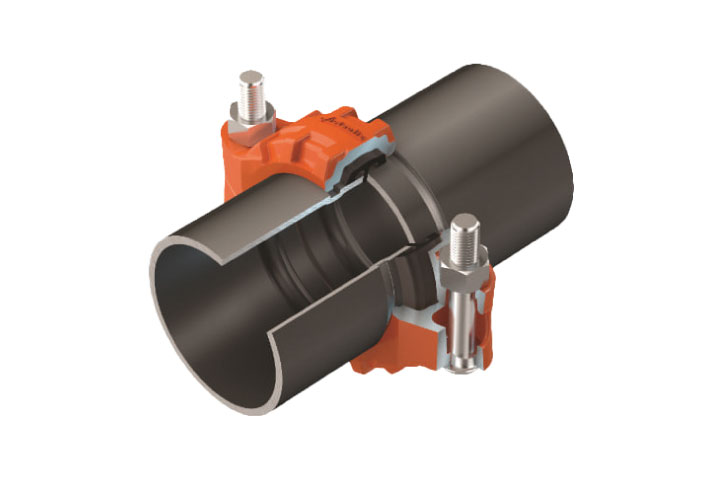

Victaulic Type Couplings

Victaulic type couplings are a type of mechanical connector that is used to join two sections of pipe or tubing together. They are typically used in piping systems for industrial and commercial applications, such as power plants, oil refineries, and chemical plants.

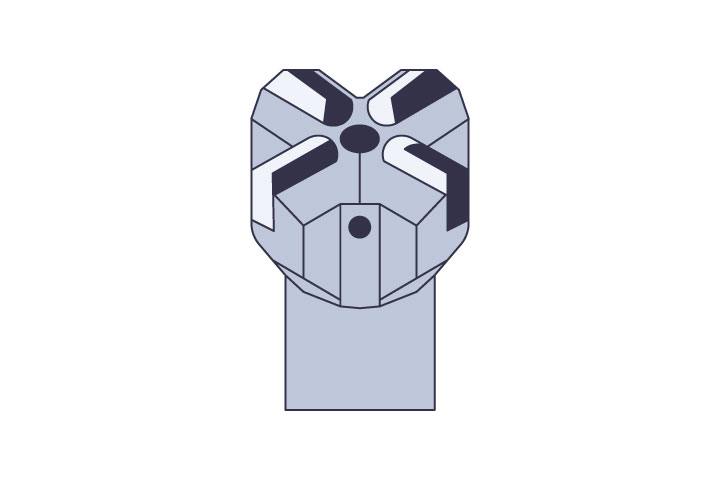

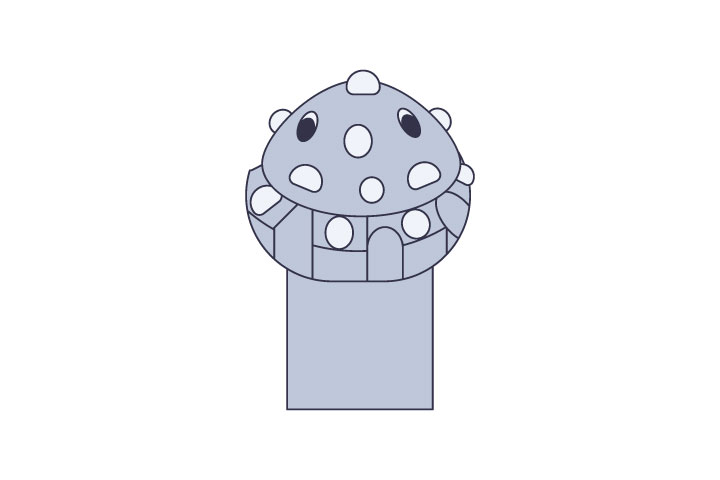

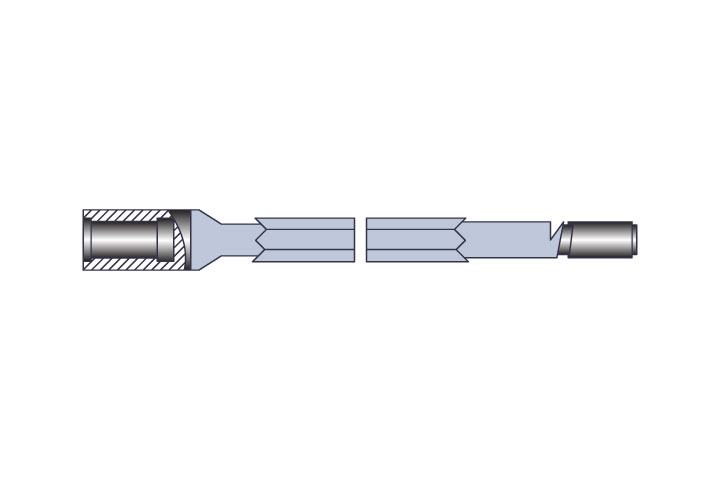

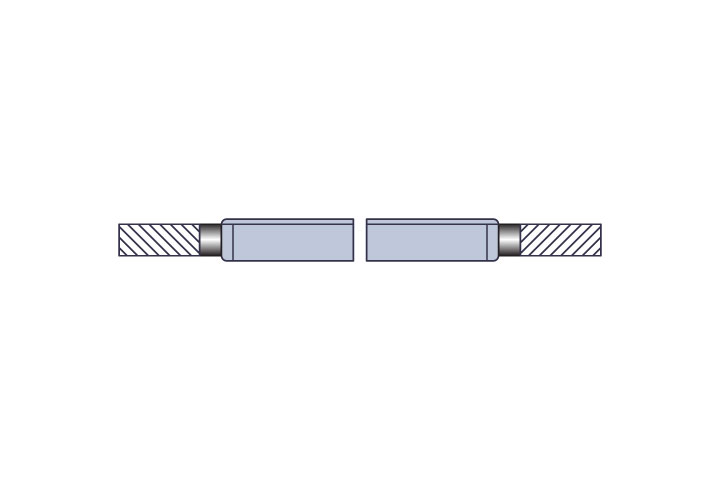

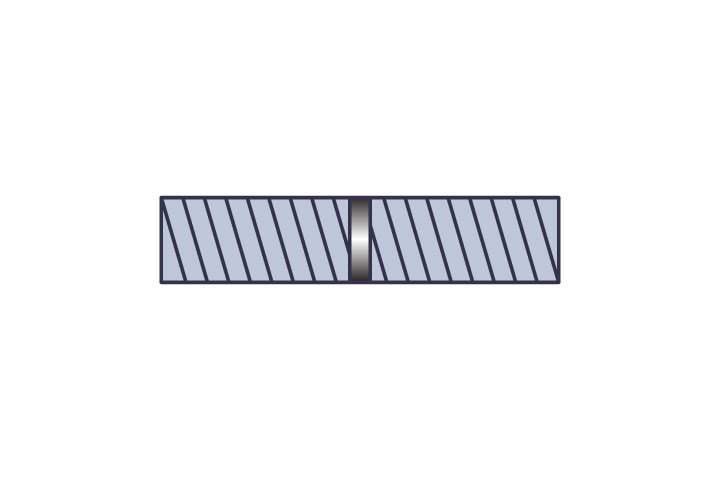

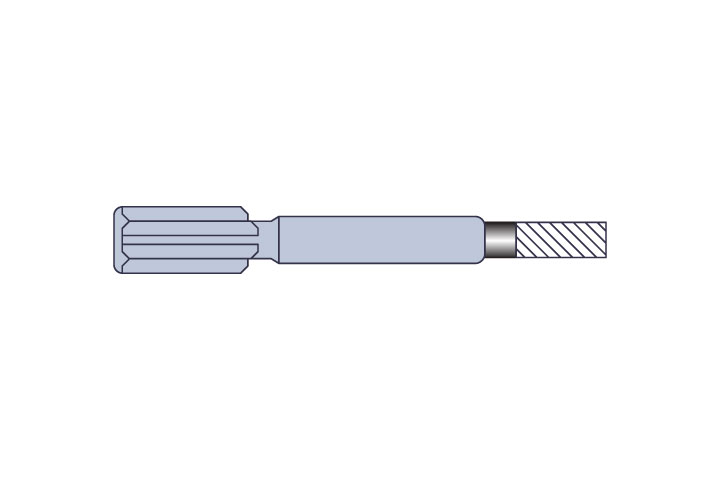

Victaulic type couplings are characterized by their unique design which allows for quick and easy installation without the need for welding or threading. They consist of two grooved ends that are brought together and then locked in place using a specialized mechanical fitting, such as a bolt or a cam-locking mechanism.

Victaulic type couplings are available in different sizes and styles, depending on the intended use. They can be used with a variety of pipe materials such as steel, stainless steel, PVC and others. They can be used in pressure or non-pressure applications, and can be used in temperatures ranging from -20 to +1000 degrees Fahrenheit.

One of the main advantages of Victaulic type couplings is that they are easy to install and require no special tools or skills. They also provide a secure and stable connection, that can withstand high pressures and temperatures. They are resistant to corrosion and vibration, and can be used in hazardous areas.

It is important to use the correct Victaulic type coupling for the task and to make sure that the coupling is well-maintained and in good condition. It is also important to follow proper installation techniques and safety guidelines when using Victaulic type couplings to avoid accidents and injuries.